5 Proven Strategies for Reducing Industrial Noise and Meeting OSHA Compliance

Highlights

Understanding the OSHA Noise Standard

Industrial facilities are often loud environments. The sound from machinery, processes, and equipment is a common part of daily operations. However, when noise levels become too high, they stop being a simple byproduct and become a serious workplace hazard. Exposure to excessive noise can cause permanent hearing loss, increase employee stress, and contribute to workplace accidents. For facility managers and safety professionals, reducing industrial noise is a critical responsibility for both employee well-being and legal compliance.

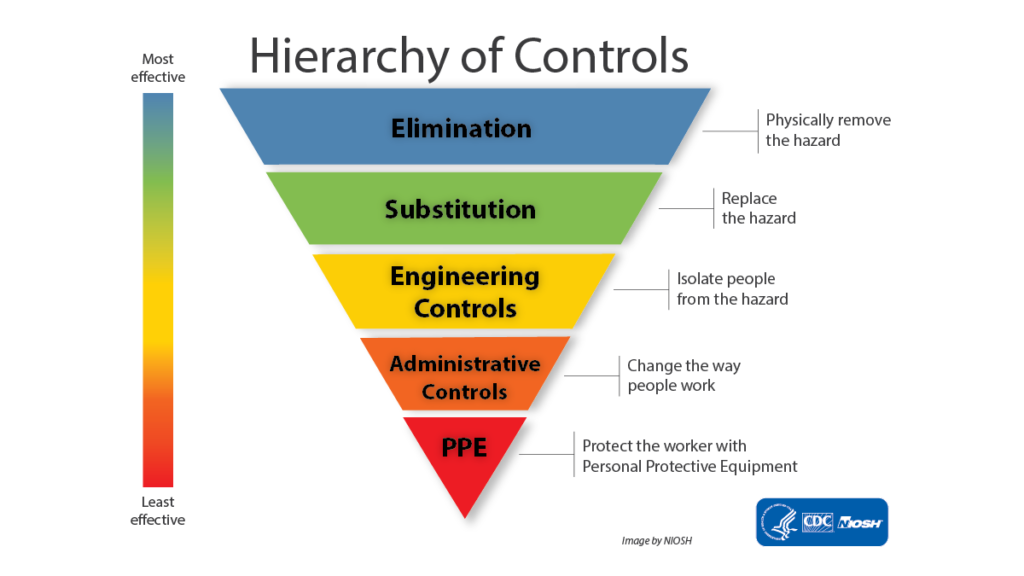

The U.S. Occupational Safety and Health Administration (OSHA) has strict regulations for protecting workers from noise. Meeting these standards requires a clear and effective strategy. This article outlines five proven strategies for reducing industrial noise in your facility. These methods are based on the Hierarchy of Controls, a framework developed by the National Institute for Occupational Safety and Health (NIOSH) that ranks safety solutions from most to least effective. Following this guide will help you create a safer, quieter workplace and ensure you meet your OSHA compliance obligations.

Before implementing any noise control strategy, it is important to understand the legal requirements. OSHA’s Occupational Noise Exposure standard sets the rules for workplace noise. The standard establishes two critical thresholds:

1. The Action Level: An 8-hour time-weighted average (TWA) exposure of 85 decibels (dBA). When employee exposure reaches this level, the employer must implement a formal Hearing Conservation Program.

2. The Permissible Exposure Limit (PEL): An 8-hour TWA exposure of 90 dBA. Employers must use feasible engineering or administrative controls to keep exposures below this limit.

A Hearing Conservation Program is a comprehensive effort that includes noise monitoring, employee training, hearing protection, and annual hearing tests (audiograms) to track employee hearing health over time.

The Framework: The NIOSH Hierarchy of Controls

The most effective way to approach any workplace hazard, including noise, is by using the hierarchy of controls. This framework prioritizes control methods in five levels, from most effective to least effective. The strategies for reducing industrial noise should always be considered in this order.

The following five strategies are based directly on this proven model.

Strategy 1: Elimination (Most Effective)

For many applications, certain STC levels are considered standard. For example, the International Building Code (IBC) requires a minimum STC rating of 50 for wall and floor assemblies separating different dwelling units (e.g., in apartment buildings or hotels). This is considered the threshold for providing good sound isolation and minimizing noise complaints between neighbors. For more sensitive spaces, like conference rooms or executive offices, an STC of 55 or higher is often specified.

Examples of Elimination:

Strategy 2: Substitution

For many applications, certain STC levels are considered standard. For example, the International Building Code (IBC) requires a minimum STC rating of 50 for wall and floor assemblies separating different dwelling units (e.g., in apartment buildings or hotels). This is considered the threshold for providing good sound isolation and minimizing noise complaints between neighbors. For more sensitive spaces, like conference rooms or executive offices, an STC of 55 or higher is often specified.

Examples of Elimination:

Strategy 3: Engineering Controls (The Technical Solution)

Engineering controls are physical changes to the workplace that reduce noise levels at the source or along the path to the worker. This strategy is the core of technical noise control and is often the most durable and reliable long-term solution for existing facilities. Our work in Industrial Noise & Vibration Control focuses heavily on these solutions.

Engineering controls can be broken down into three main categories:

Control at the Source: This involves modifying the noisy machine itself to make it quieter.

Control Along the Path: This involves placing a barrier between the noise source and the employee.

Control at the Receiver: This is less common but can involve creating a quiet space for the worker.

The NIOSH Engineering Controls Database is an excellent resource for exploring proven solutions for specific industries and equipment.

Strategy 4: Administrative Controls

Administrative controls change how and when employees work to limit their noise exposure. These controls do not reduce the noise itself but reduce the dose of noise an employee receives over a shift. They are often used in combination with engineering controls.

Examples of Administrative Controls:

Strategy 5: Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is the last line of defense against hazardous noise. PPE for noise includes earplugs and earmuffs. When engineering and administrative controls cannot reduce noise exposure to safe levels, employers must provide PPE to their employees.

While necessary, PPE is considered the least effective control method for several reasons:

The Framework: The NIOSH Hierarchy of Controls

Reducing industrial noise is a critical part of any effective safety program. By using the NIOSH Hierarchy of Controls as a guide, facility managers can move beyond simply handing out earplugs and implement more durable and effective solutions.

While all five strategies have their place, a focus on engineering controls provides the most reliable protection for employees and the most dependable path to long-term OSHA compliance. A well-designed acoustic enclosure or a properly silenced machine protects every worker in the area, every shift, without requiring individual action.

If your facility is facing challenges with hazardous noise, a professional assessment is the best first step. To discuss your specific needs for noise monitoring or engineering control design, please contact us for a consultation.